Soft Magnetic Nickel Iron Alloy Powder (FeNi)

Nickel iron soft magnetic alloy powder is a kind of magnetic permeability under low magnetic field (μ)

soft magnetic alloy powder with very high coercivity (Hc). It contains 30-90% nickel or a small amount of other elements.

Nickel iron alloy powder

Nickel iron alloy powder can be divided into the following categories:

Nickel Iron Alloy Powder with High Resistivity

Nickel iron alloy powder with high resistivity is a kind of nickel iron alloy powder with nickel content about 36%. The resistivity of this ferronickel alloy is about 75% μΩ· It has low eddy current loss, low initial permeability (2000-3000) and almost unchanged in low magnetic field. When 2% Mo is added to 34.5 Ni Fe alloy, the secondary recrystallization texture is obtained after cold rolling and annealing with a reduction of more than 90%. The saturation magnetostriction decreases, the initial permeability increases obviously (55000), and the resistivity increases to 90% μΩ· Cm, suitable for medium frequency applications.

High Saturation Magnetic Induction Nickel Iron Alloy Powder

High saturation magnetic induction nickel iron alloy powder is a kind of nickel iron alloy powder with nickel content of 45% ~ 60%. The saturation magnetic induction of the alloy is about 1.6T and the initial permeability is high (3000-6000). Secondary recrystallization texture was obtained by cold rolling and annealing with about 95% reduction, μ0 can be increased to 10000. The most commonly used (47 ~ 50) Ni-Fe alloy can be treated by magnetic field heat treatment μ0 and μ. The m value is further increased by 3-4 times.

Nickel Iron Alloy Powder with High Magnetic Conductivity

Nickel iron alloy powder with high magnetic conductivity refers to a kind of nickel iron alloy powder with 74% - 82% nickel content. The initial permeability of the alloy is 30000-100000, the maximum permeability is 100000-300000, and the coercivity is very low. The cooling rate after annealing has a great influence on the magnetocrystalline anisotropy and permeability, which is related to the formation of FeNi3 ordered structure. A small amount of Mo, Cr and Cu are often added in order to decrease the rate of ordered transformation and increase the resistivity. Molybdenum and chromium atoms replace part of iron atoms, copper atoms replace part of nickel atoms, which can prevent the formation of FeNi3, thus simplifying the heat treatment operation and increasing the permeability. The most commonly used high permeability Ni-Fe alloys are 4-79 Mo permalloy, Mumetal (5% Cu, 2.75% Cr and 77% Ni or 4% Mo, 5% Cu and 77% Ni) and super permalloy containing 5% mo. Adding 2-3% Ti or 3-7% Nb to Ni Fe alloy with high magnetic conductivity can form very fine precipitates, hinder dislocation movement, improve hardness and wear resistance, and maintain high permeability. It is called hard permalloy, which is often used as magnetic head material.

Nickel Iron Alloy Powder with Constant Magnetic Conductivity

Constant magnetic

ferronickel alloy powder is a kind of ferronickel alloy powder with 50% nickel content. It is Fe-Ni50 alloy powder. The characteristic of this kind of Ni-Fe alloy is that the permeability does not change with the intensity of magnetic field, the hysteresis loop is inclined and the remanence is very low. The isoperm alloy of Fe-Ni50 (sometimes with a small amount of copper or aluminum) is magnetized along the rolling direction after cold rolling with a reduction of more than 90% and annealing at 1000 ℃, and then cold rolling with a reduction of 50%. The loop is inclined, the br value is very low, and the permeability almost does not change with the size of the magnetic field.

After transverse magnetic field heat treatment, the loops of Fe-Ni65 alloy (or adding 1% Mn), perminvar type alloy [(34-45) Ni-(25-29) Co-Fe or adding 2-3% Mo and Nb] and 79Ni-4Mo-Fe alloy are also inclined, with higher and constant permeability. The Fe-Ni65 alloy containing 1% Mn has the best comprehensive properties such as permeability stability, temperature stability and effective permeability.

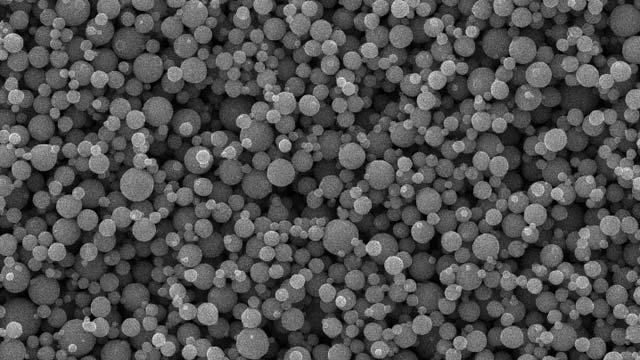

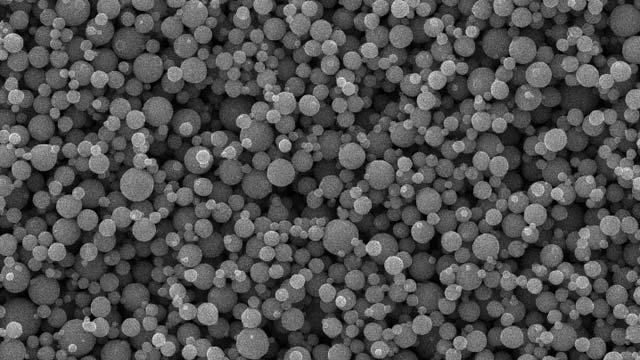

At present,

FUSNANO can supply large quantities of

FeNi50 alloy powder with micro and nano constant magnetic conductivity. At present, the production capacity is more than 5 tons per month. The average particle size of NiFe alloy powder is 0.5um-2um. Ni/Fe: 50/50 wt%。 At the same time, we can also customize nano ferronickel powder below 0.5um according to the needs of customers, and we can also customize ferronickel powder with different composition proportion according to the needs of customers, such as 6:4, 7:3 and so on. To purchase ferronickel powder, please click the link to enter the product page:

Ferronickel Alloy Nanopowder